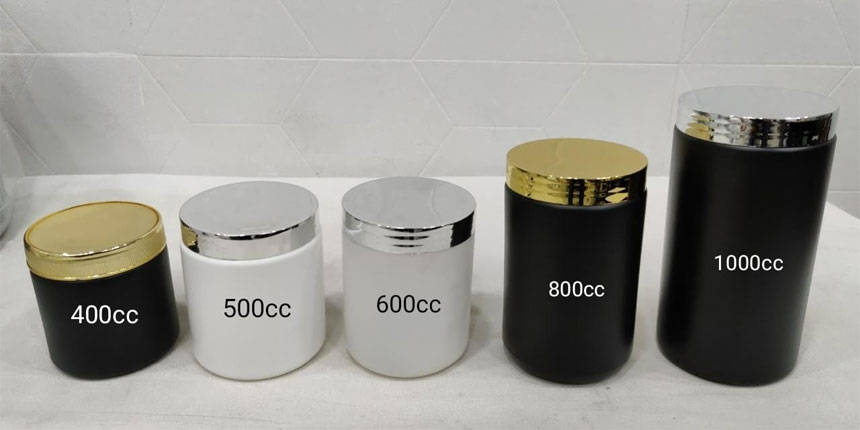

When selecting the right packaging for your cosmetic products, understanding the difference between standard and overflow capacities is crucial. This ensures not only compliance with industry regulations but also enhances customer satisfaction by accurately representing the amount of product they receive.

Here’s a comprehensive guide to help you determine the capacity of your cosmetic container.

Standard Capacity

Standard capacity refers to the amount of product a container can hold under normal conditions, typically measured by filling the container to a level where it is considered full without any spillage. This is the practical capacity you should consider when specifying the amount of product to be sold.

- Practical Usability: Standard capacity reflects the usable amount of product that a consumer can extract from the container.

- Regulatory Compliance: Many regions have regulations specifying how product volume should be communicated to consumers, often based on standard capacity.

- Consumer Expectation: Aligns with what consumers perceive as a full container, helping to meet their expectations and avoid dissatisfaction.

Overflow Capacity

Overflow capacity measures the maximum volume a container can hold if it is filled to the absolute top, just before spillage occurs. This measure is often used in the design phase to understand the total volume potential of the container.

- Maximum Volume: Indicates the total space available within the container, useful for design and engineering purposes.

- Not Practical for Use: This capacity is not suitable for real-world usage as it does not account for the need to avoid spillage and allow for product dispensing.

Determining the Right Capacity for Your Product

Identify the Product Type:

- Liquids and Creams: For these products, it’s essential to consider how they will flow and be dispensed. The standard capacity should account for the ease of use without causing a mess.

- Powders and Solids: These may settle over time, so the standard capacity might need to consider compaction and settling.

Consider Usage and Dispensing Method:

- Pump or Sprayer: These mechanisms often require some space within the container to function properly, influencing the standard capacity.

- Jar or Tube: With these containers, the ease of accessing the product (e.g., with a finger or applicator) should determine how full the container should be filled.

Regulatory Requirements:

- Ensure you are aware of the regulations in your target markets. For example, the U.S. Fair Packaging and Labeling Act mandates clear labeling of net contents, often based on standard capacity.

Testing and Feedback:

- Conduct practical tests to determine how consumers use the product. This will help in deciding the optimal standard capacity.

- Gather feedback to ensure the capacity meets consumer expectations and practical usability.

Labeling Considerations:

- Clearly indicate the net weight or volume on the packaging, based on the standard capacity. Avoid using overflow capacity as it can be misleading.

Example Calculation

- Scenario: You have a 100 ml container for a facial cream.

- Overflow Capacity Test: Fill the container to the brim; it holds 105 ml.

- Standard Capacity Test: Fill the container to a practical level where the cream can be dispensed easily without spilling; it holds 95 ml.

In this case, the standard capacity would be 95 ml, which is the volume you should indicate on your packaging and use for pricing.

Conclusion

Choosing between standard and overflow capacities is not merely a technical decision but a crucial aspect of product development that impacts regulatory compliance, consumer satisfaction, and brand trust.